PRODUCTS

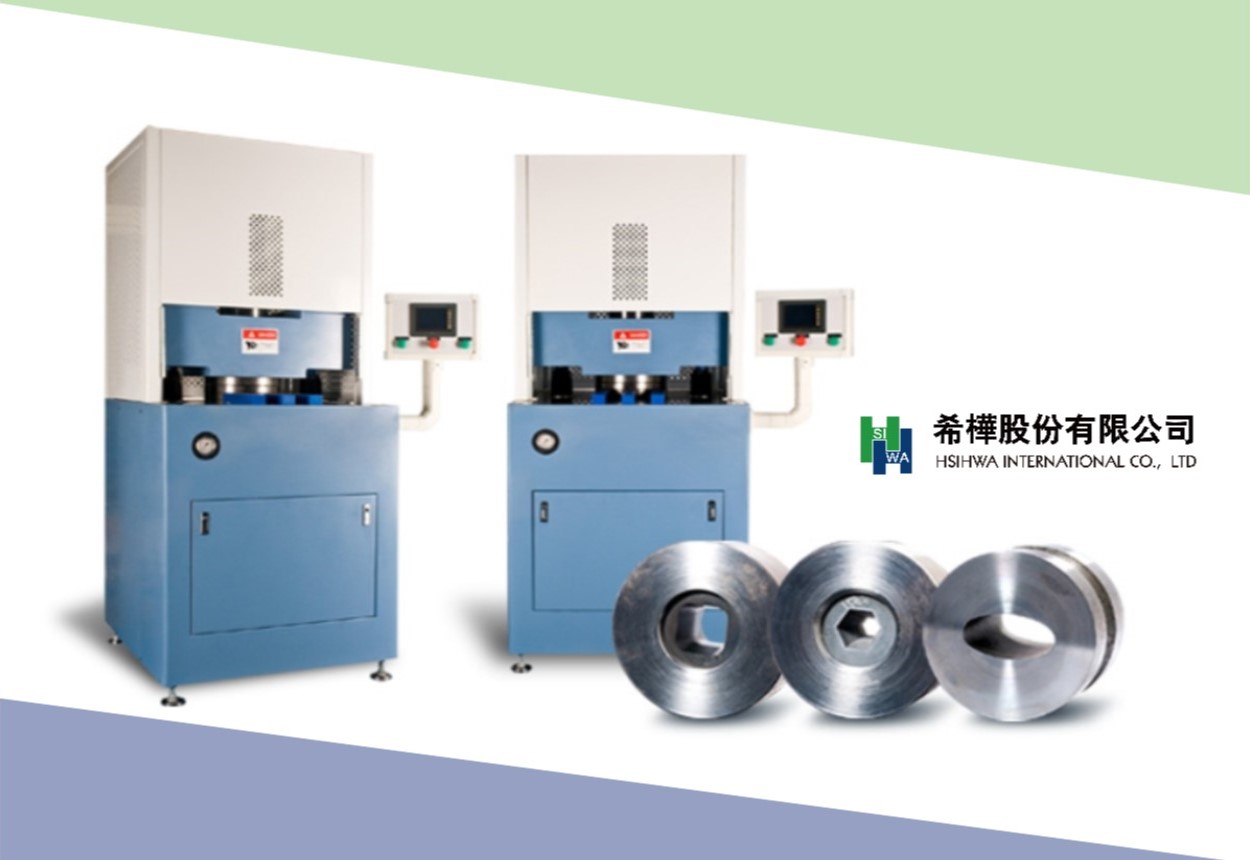

AFM FLOW POLISHING MACHINE

AFM FLOW POLISHING MACHINE

Model ID:AFM - HSIHWA

★Flow Polishing Machine, different from conventional processing mode, applies squeeze-flow method to perform mirror polishing and burr removing on hetero-form, irregular surface and inner hole, slim seam and micro hole work pieces.

★Flow polishing adopts the latest grinding –polishing method, which allows detail grinding processing depends on the technical requirements, and it can attain mirror effect polishing, or solving attachment difficulty in surface treatment depends on characteristics of materials and pre-processing conditions.

★Flow Polishing is achieved with polishing media which is made of soft resin plus high fluidity colloid and added with grinding particles based on the grinding or polishing needs. The special soft, flow media has high fluidity and contains high concentration of abrasive and it is arranged to pass through the surface of work pieces in up-down movement.

Flow Polishing is achieved with polishing media which is made of soft resin plus high fluidity colloid and added with grinding particles based on the grinding or polishing needs. The special soft, flow media has high fluidity and contains high concentration of abrasive and it is arranged to pass through the surface of work pieces in up-down movement.

★In AMF Polishing, the work piece is placed on machine working table and held with tooling. The media tank at the upper side of machine and fixing seat fix the work piece from upside down with hydraulic cylinder. When the upper and lower media tank are filled with media, it moves to push the media upward to the top point then downward to the lowest point. In such up/ down movement, the polishing effect is achieved with set cycle times and quantity of media in the flow.

Hsihwa developed independently and produces special grinding / polishing material:

The raw materials are imported from Europe / USA with features of high fluidity, even surface grinding/ polishing effect, good coagulation and mirror-processing effect. Good coagulation gives longer service to the media and it is less likely to sediment.

High Fluidity:Subject to hole dimension and size of work piece (between 0.1 mm to 500 mm), flow media of different hardness may be selected:

Hard No.5 : About 80 degree (rubber hardness) suitable for cast auto parts with large hole.

Medium Hard No.4 : About 60 degree (Rubber Hardness) suitable for Pressing machine, Punching machine working piece of large mold.

Medium No.3: About 40 degree (Rubber Hardness) Tungsten Carbide Die, Knitting Machine parts.

Soft No.2: About 10-15 degree (Rubber Hardness) for burr removing , inner hole grinding and polishing.

Ultra Soft No.1: (Liquid) special for micro hole, slim seam, nozzle and semiconductor work piece.

Even grinding of polishing surface: Abrasive can be carborandum, Boron Carbide with good cutting effect to attain high speed effect in grinding,

polishing, burr removing and chamfering.

Particle size: Abrasive particles are available between #8 mesh (average 4.82 mm) to #1200 mesh (0.015 mm) for different application / effect.

Mirror Surface Treatment : With extra grade diamond particles and special polishing powder, HSIHWA’s product can polish special work piece and reach

mirror effect.

M03: is designed for polish of Tungsten Carbide work piece with removal of 25-40 um and surface brightness of Ra 0.08 um.

F02 : for work piece requires high precision like precision mold and continuous stamping mode, with polished surface brightness of Ra 0.04 um with

removal of 10 um.

Excellent Coagulation Effect: Media is produced with high precision equipment with 100% coagulation. Depends on the needs of application, the

abrasive concentration may be as high as 90%, which featured with cost saving and fast processing effect. It is far

different from conventional low abrasive concentration resin.

High concentration can accelerate cutting and is much faster than ordinary media polishing.

Good coagulation gives longer service to the media and it is less likely to sediment.

★Flow polishing adopts the latest grinding –polishing method, which allows detail grinding processing depends on the technical requirements, and it can attain mirror effect polishing, or solving attachment difficulty in surface treatment depends on characteristics of materials and pre-processing conditions.

★Flow Polishing is achieved with polishing media which is made of soft resin plus high fluidity colloid and added with grinding particles based on the grinding or polishing needs. The special soft, flow media has high fluidity and contains high concentration of abrasive and it is arranged to pass through the surface of work pieces in up-down movement.

Flow Polishing is achieved with polishing media which is made of soft resin plus high fluidity colloid and added with grinding particles based on the grinding or polishing needs. The special soft, flow media has high fluidity and contains high concentration of abrasive and it is arranged to pass through the surface of work pieces in up-down movement.

★In AMF Polishing, the work piece is placed on machine working table and held with tooling. The media tank at the upper side of machine and fixing seat fix the work piece from upside down with hydraulic cylinder. When the upper and lower media tank are filled with media, it moves to push the media upward to the top point then downward to the lowest point. In such up/ down movement, the polishing effect is achieved with set cycle times and quantity of media in the flow.

Hsihwa developed independently and produces special grinding / polishing material:

The raw materials are imported from Europe / USA with features of high fluidity, even surface grinding/ polishing effect, good coagulation and mirror-processing effect. Good coagulation gives longer service to the media and it is less likely to sediment.

High Fluidity:Subject to hole dimension and size of work piece (between 0.1 mm to 500 mm), flow media of different hardness may be selected:

Hard No.5 : About 80 degree (rubber hardness) suitable for cast auto parts with large hole.

Medium Hard No.4 : About 60 degree (Rubber Hardness) suitable for Pressing machine, Punching machine working piece of large mold.

Medium No.3: About 40 degree (Rubber Hardness) Tungsten Carbide Die, Knitting Machine parts.

Soft No.2: About 10-15 degree (Rubber Hardness) for burr removing , inner hole grinding and polishing.

Ultra Soft No.1: (Liquid) special for micro hole, slim seam, nozzle and semiconductor work piece.

Even grinding of polishing surface: Abrasive can be carborandum, Boron Carbide with good cutting effect to attain high speed effect in grinding,

polishing, burr removing and chamfering.

Particle size: Abrasive particles are available between #8 mesh (average 4.82 mm) to #1200 mesh (0.015 mm) for different application / effect.

Mirror Surface Treatment : With extra grade diamond particles and special polishing powder, HSIHWA’s product can polish special work piece and reach

mirror effect.

M03: is designed for polish of Tungsten Carbide work piece with removal of 25-40 um and surface brightness of Ra 0.08 um.

F02 : for work piece requires high precision like precision mold and continuous stamping mode, with polished surface brightness of Ra 0.04 um with

removal of 10 um.

Excellent Coagulation Effect: Media is produced with high precision equipment with 100% coagulation. Depends on the needs of application, the

abrasive concentration may be as high as 90%, which featured with cost saving and fast processing effect. It is far

different from conventional low abrasive concentration resin.

High concentration can accelerate cutting and is much faster than ordinary media polishing.

Good coagulation gives longer service to the media and it is less likely to sediment.

SPECIFICATION